Quality control

We offer leading non-contact measurement systems and 3D scanning solutions. Our solutions are designed to help manufacturing organizations to reduce their time-to-market and their overall production costs, and to improve the quality of their products.

Turbine Blade

Turbine Blade

Turbine Blade 1. Part

Part

Part

A customer from the aeronautics sector needs to perform quality control on a blade used in a plane's turbine.

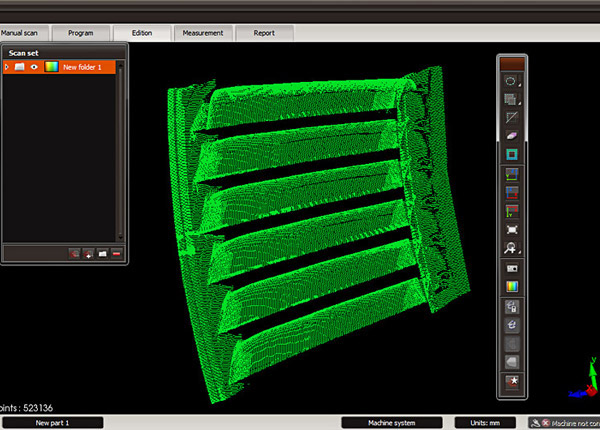

2. scanning

scanning

scanning

Once we have received and documented the part, we start the high-definition 3D scanning process with M3 Portable.

3. 3d point cloud

3d point cloud

3d point cloud

Visualization of high-fidelity 3D point cloud information for geometrical features extraction and surfaces analysis.

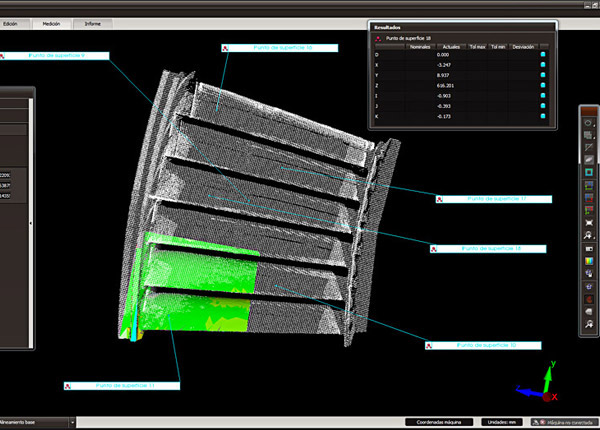

4. analyze

analyze

analyze

We use the customer's validation standards to analyze the point cloud obtained with the high precision OptiScan laser sensor.

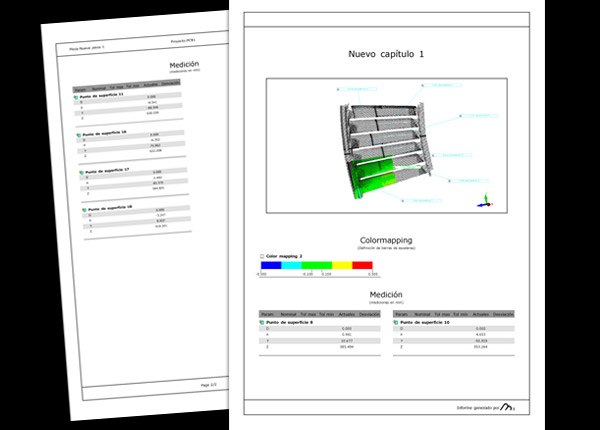

5. reports

reports

reports

A customized report is emailed to the client, containing a detailed analysis of the part according to their specifications as well as all of the data gathered during the scanning process.